| |

Connector welding consists in joining metal pieces , normally in the form of rods to metal supports . It is used mainly in bridge building (especially in mixed structures ), steel structures , facades and walls.

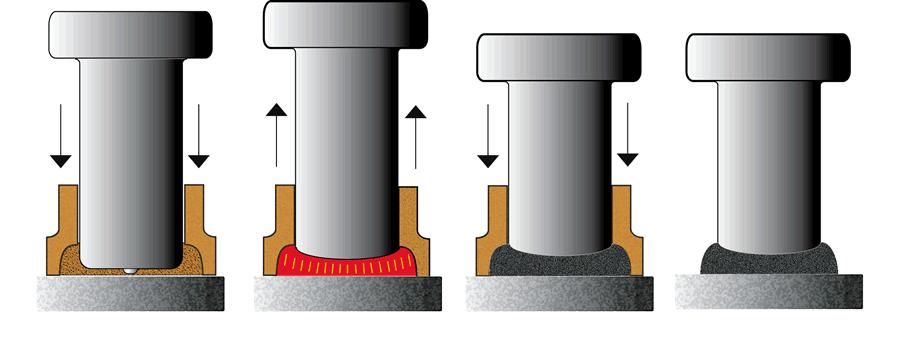

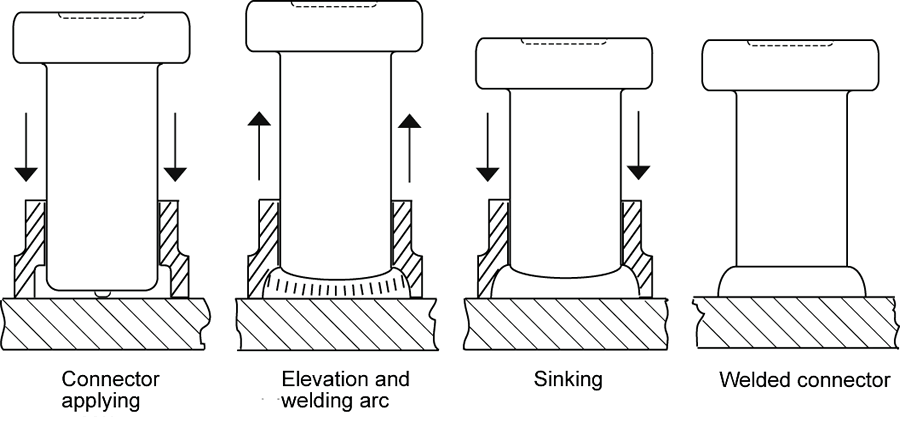

In the welding arc process connectors are primed briefly between the connector end to be welded and the workpiece : the two parts begin to melt and join together. For proper welding, using the method of arc welding by melting and forging, this can be done mechanically or automatically , using welding guns or heads . The different phases of welding are shown in the drawings below . The connector is inserted into its support and fitted with a ceramic ferrule ,it is applied to the workpiece. At the beginning of the welding process , the connector is raised by the mechanism and , in general , provides an auxiliary arc followed by the main arc between the connector end and the workpiece. This causes the fusion of the plug end and the base material. When welding time has elapsed , the connector is immersed in the molten pool with a specified force (< 100 N ) and the current source is disconnected.

This process is generally used in a range of diameters between 3 mm and 25 mm, with a welding time of 100 ms to 3000 ms. It´s generally performed with ceramic ferrules , and only in certain cases, with or without shielding gas or weld pool protection . The minimum thickness of the sheet is 1/4 the diameter of the connector for welding with CF and 1/8 of the diameter in the case of welding with SG , but can not be less than 1 mm.

Symbols and Abbreviations

P - Protrusion(1)

L - Elevation

CF - ceramic ferrule

SG - Shielding Gas

DS - Arc Welding of connectors by melting and forging

NP - No protection

( 1 )

The protrusion is the distance between the connector end and the connector support device in its initial position against the plate

support. |

|